Kids ask a bazillion questions. At least mine do, especially my middle one. So when I’m asked things like “how long does it take to build an airplane?”, I’m thankful that I can turn to Google for an answer. As dad I’m apparently expected to know the answer to every question, even off-the-wall things like “what if our hair grew an inch every second?”. That, I have to assume, is rhetorical and doesn’t warrant an answer.

But at least I can answer many others. Living in the age of the internet has it’s upside. Otherwise I might have to find a time to walk two whole blocks down to the library and consult *gasp* books.

At least this question is one that piqued my interest. So I figured I’d compile my research into a blog post.

How Long Does It Take To Build A Commercial Airplane?

The time it takes to build a commercial jet depends on several factors. Are we building a narrow-body or a wide-body? What is the typical throughput of the assembly line? How many people are dedicated to each aspect of manufacturing an assembly?

The other question is whether we’re talking strictly assembly or the whole manufacturing process. When I toured Boeing’s factory in Everett with one of my boys, the tour guide noted that the plant is more an assembly space that how you might imagine manufacturing. Various components are sent to Everett from numerous suppliers, and what happens in the factory is more assembly than anything.

The size of the jet matters, of course, but likely less so that it would. The most popular aircraft (think Boeing 737) need to be assembled and shipped of like hotcakes (at least…they did pre-coronavirus). For types where there are very few orders on the books, like the Boeing 747-8i, these have not moved as fast. Assembly time is definitely affected by the order timeline.

There is also painting time to consider. Putting on the shiny livery is its own can of worms, but this can typically be done in a week, if things move quickly. Then the bird needs to be tested. I’m really looking for time from the first pieces are connected through to delivery, so it makes sense to include everything. But not all these numbers are readily available.

Researching the assembly to delivery time of various jets, here are the best numbers I can find (pre-COVID-19):

- Embraer 175: Can’t find a definitive answer.

- Airbus A220 Series: Looks like up to 4 per month in a few year? So maybe eventually just 7-8 days for assembly?

- Boeing 737MAX Series: 25-40 days (assembly can take just 9 days!)

- Airbus A320 Series: Can’t find a definitive answer. Airbus was producing over 60 per month.

- Boeing 787 Series: 25-40 days

- Airbus A350 Series: ~2.5-3 months

- Boeing 777: 50-60 days (~17 for assembly!)

- Boeing 747-8i: 3-4 months

- Airbus A380: ~80 days for assembly

The numbers are likely not exact and are gathered from a variety of sources. But they should be fairly representative. As one would suspect, wide-body aircraft generally take longer than narrow-body planes and regional jets.

If you include supplier lead time into the equation (parts are sent to the assembly plants from all over the world), then it takes 9-12 months to build an aircraft. Really depends how you look at it.

Case Study: Boeing 737 vs. Boeing 777

One would think that it would take longer to build a wide-body than a singe-aisle aircraft, not only because of the difference in size, but also because of the number of these babies Boeing cranks out every month. The Boeing 737 series is the most successful commercial passenger jet ever produced, and Boeing hit the 10,000 mark in 2018. The current iteration is worlds different than the original 737, holding over twice as many people and flying substantially farther.

Given the backlog of over 4,000 Boeing 737 airplanes versus the less than 400 on the books for the 777-300ER and 777X (not yet launched), Boeing puts together many, many more of the 737s and much more quickly. The 737 is both much smaller, plus it requires far greater throughput, given the number of orders.

Hence the difference in assembly times. The Boeing 737 takes a crazy fast 9 days for assembly, while the 777 takes approximately 17 days.

Conclusion

So how long does it take to build a commercial airplane? It depends on the airplane, but in general, you can’t construct one in less than a couple months, if you include all phases of production. And this is for the most popular jets that are being produced as quickly as possible!

Sure, production didn’t start out this fast. But with massive order books and the need to get planes out as quickly as possible (at least until this year), improving efficiency dramatically increases the manufacturer’s revenue and profit. For example, the 777 assembly time dropped from 49 days in 2012 to just 17 in 2019. That’s crazy.

No matter how you want to tally up the days, the amount of time it takes to build a commercial airplane is remarkably short, considering how complex planes are.

Unfortunately, one cannot calculate the total time it takes to produce one aircraft based upon the output volume of aircrafts per unit time. This is because there can both be multiple aircraft being simultaneously assembled side by side (which would increase the amount of aircraft completed per unit time by 1x 2x 3x etc for each additional line open), and also because there is likely a many-step queue where there are multiple aircraft in each line in various states of completion in the queue; this would make it appear as planes are completing at a very fast rate as each plane may online take a week to complete each step (in this case, then a plane-per-week would be completed), but i may have been a 10 step queue, making the total time each aircraft was being assembled 10 weeks from start to finish, not 1 week. Without actually knowing these variables, we cannot truly begin to estimate how long it takes for one aircraft from start to completion.

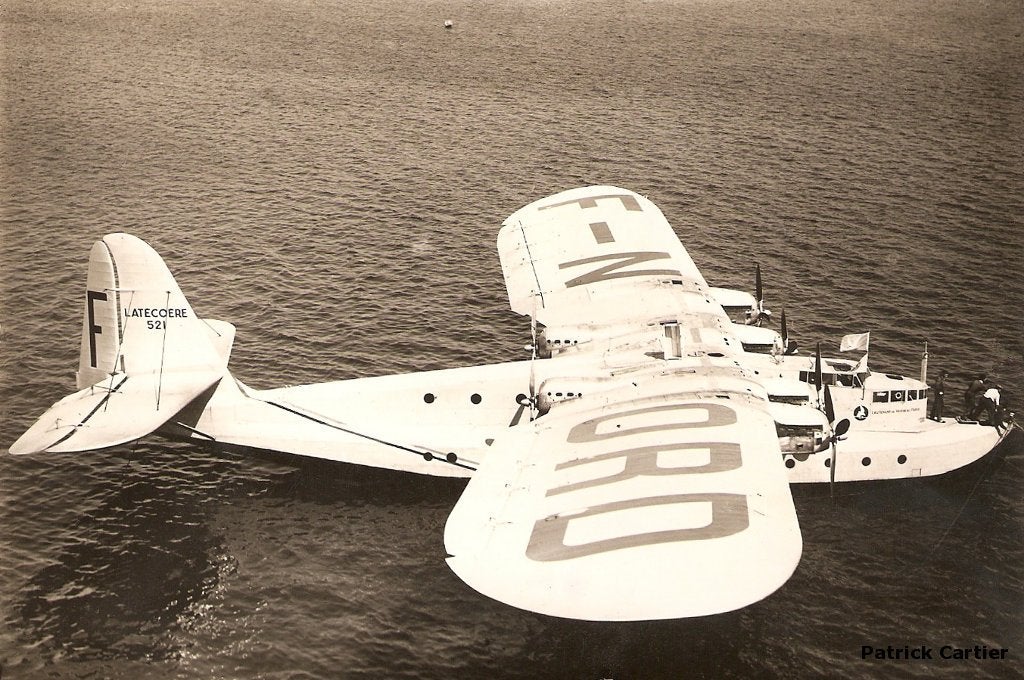

You should take a look at the numbers of B24 bombers produced by the Ford plant during WWII. It was how many per DAY!

That’s crazy! Those are admittedly “simpler” in terms of systems. But still an incredible feat.